Vacuum sealing is a popular method for extending the shelf life of food. By removing oxygen from the packaging, this technique inhibits the growth of many spoilage-causing microorganisms and prevents oxidation, which can degrade food quality. But exactly How Long Does Vacuum Packed Food Last? This article provides a detailed look at the shelf life of various foods when vacuum-sealed, offering valuable insights for both home cooks and food industry professionals.

Vacuum sealing can extend the shelf life of food products significantly, sometimes up to five times longer than traditional storage methods. This makes it an excellent option for preserving food quality and reducing waste. However, it’s crucial to understand that vacuum sealing isn’t a foolproof method; food will eventually spoil or degrade, even in the absence of oxygen.

What is Vacuum Sealed Food?

Vacuum-sealed food refers to food items that are packaged in an airtight container or bag from which air has been removed. This process, also known as Reduced Oxygen Packaging (ROP), minimizes the presence of oxygen, which is essential for the growth of many spoilage bacteria and molds. In some cases, an oxygen absorber packet is added to the packaging for added protection.

Vacuum sealing also helps to preserve the flavor and aroma of food by preventing the loss of volatile compounds and reducing oxidation. For example, vacuum-sealed meat will retain its deep purple-red color until the package is opened. Additionally, vacuum packaging can save space by reducing the bulkiness of food items, making storage and transportation more efficient.

One of the key benefits of vacuum sealing is its ability to inhibit the growth of aerobic bacteria, which require oxygen to thrive. By limiting the biological processes of these bacteria, vacuum packaging can significantly extend the shelf life of food products.

For food businesses that commercially vacuum-pack food, a Hazard Analysis and Critical Control Points (HACCP) plan is often required to ensure food safety compliance.

HACCP Plan for Vacuum Sealer: Is it Required?

Yes, a HACCP plan is typically required for food businesses involved in reduced oxygen packaging (ROP), especially for raw vegetables, raw meat, raw poultry, or related industries. This is because, while vacuum sealing inhibits some types of bacteria, others, such as Clostridium botulinum and Listeria monocytogenes, can thrive in low-oxygen environments.

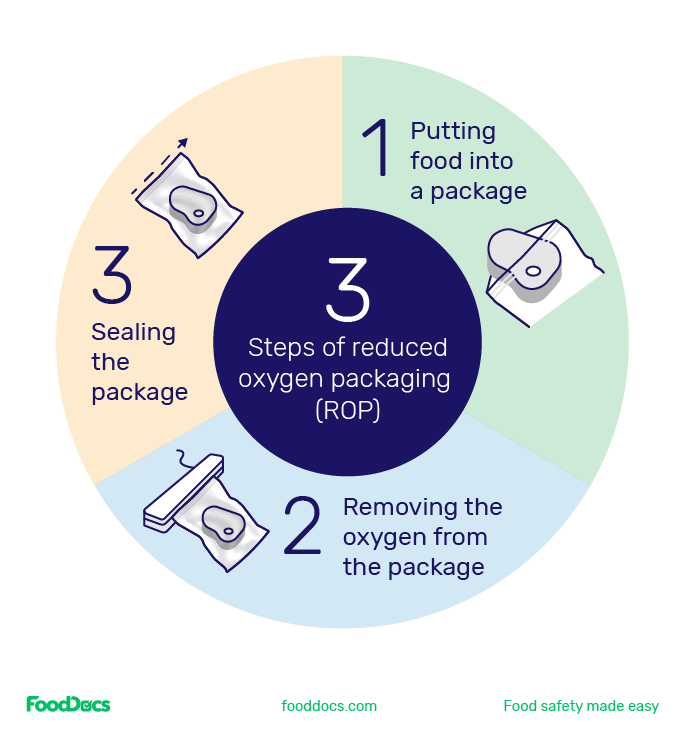

Reduced oxygen packaging involves three key steps:

- Placing food into a package.

- Removing the oxygen from the package.

- Sealing the package.

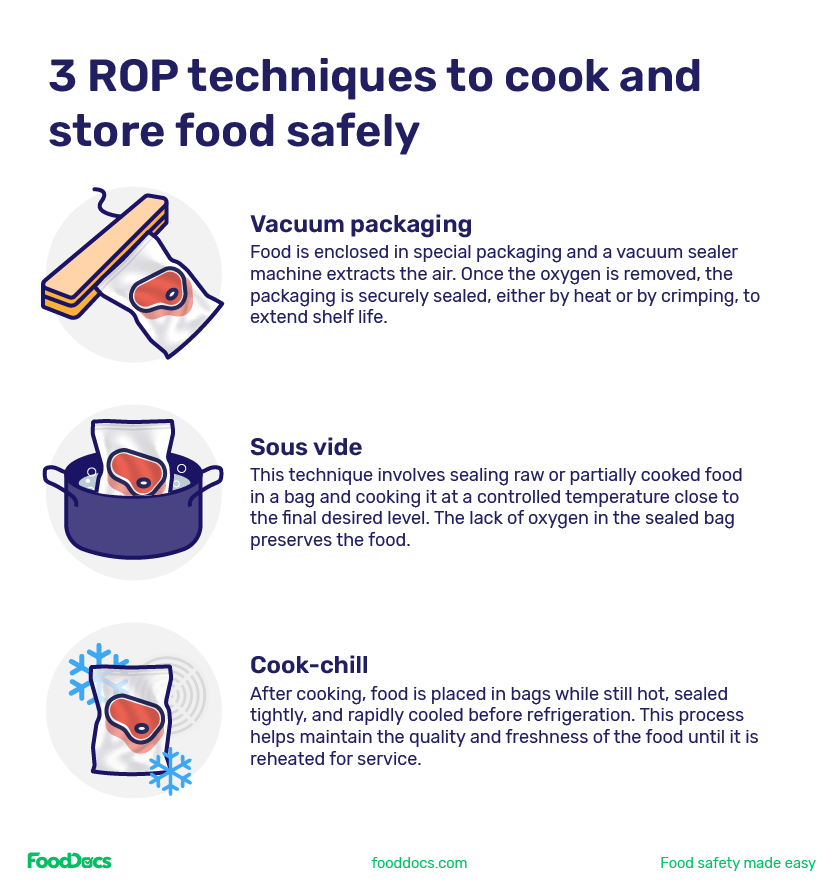

ROP techniques include:

- Vacuum packaging: A vacuum sealer machine extracts the air from a special packaging containing the food and then seals it tightly.

- Sous vide: Raw or partially cooked food is sealed in a bag and cooked at a controlled temperature. The absence of oxygen helps preserve the food.

- Cook-chill: Hot cooked food is placed in bags, sealed, and rapidly cooled before refrigeration to maintain quality and freshness.

The FDA Food Code provides guidelines for Reduced Oxygen Packaging with One Barrier (Cook-Chill and Sous Vide) for Time/Temperature Control for Safety (TCS) foods, offering four options for food storage:

- Cool to 34°F (1°C) within 48 hours: Discard if unused after 30 days.

- Keep at 41°F (5°C) for 7 days: Discard if not consumed within that time.

- Cool to 34°F (1°C) within 48 hours, then hold at 41°F (5°C) no longer than 7 days: Discard if not consumed within 30 days.

- Freeze indefinitely until used.

A comprehensive HACCP plan for food vacuum sealers should include:

| HACCP plan section | Requirements |

|---|---|

| Covered foods | Raw vegetables, raw meat, and raw poultry stored in refrigerated conditions (41°F or lower). |

| Flow diagram | Receiving, cooler storage, vacuum packaging, labeling, chilling (ice bath), and refrigerated storage (41°F or lower until used or discarded after 14 days). |

| Training program | Employee training on allowed foods, food safety risks, equipment use, labeling, handling, storage, critical and operating limits at CCPs, and cleaning procedures. |

| General operating Procedures | Operation by trained personnel, use of food-grade packaging, equipment cleaning every 4 hours or after use, and vacuum packaging only for covered foods. |

| Labeling | Products must be labeled with “Maintain at 41°F or below” and “Use by (14 days from the date of packaging).” Discard unlabeled or expired products. |

| Critical Control Points (CCPs) | Monitoring using calibrated continuous thermometers for refrigerated storage, visual checks twice a day, and daily review of data. Corrections are required if the temperature exceeds 41°F. |

| Corrective actions | If the temperature exceeds 41°F, food must be evaluated by a process authority. Unsafe products are discarded, and storage equipment must be repaired. |

| Verification | Weekly review of temperature logs and labeling checks by a manager/supervisor to ensure all critical limits are maintained. |

The Importance of a Vacuum Sealed Food Shelf Life Chart

A vacuum sealed food shelf life chart provides essential guidance for food handlers on the expected shelf life of vacuum-sealed foods. While vacuum sealing extends the life of foods, it does not prevent spoilage indefinitely. The effectiveness of vacuum sealing varies depending on the type of food.

For example, fresh meat like ground beef typically lasts for 2 to 3 days in the refrigerator. When vacuum-packed and refrigerated, its shelf life can extend up to 10 days. In contrast, lettuce may only stay fresh for 6 to 8 days, even when vacuum-packed and refrigerated.

According to Kara Lynch, a Registered Dietician and Food Safety Educator at Michigan State University Extension, “vacuum sealing reduces exposure to oxygen and can significantly extend food’s quality shelf life while reducing waste.”

Even with the benefits of vacuum sealing, it is important to educate food handlers about how long the storage life of specific foods would be. A vacuum-sealed food storage life chart can serve as a reference for labeling vacuum-sealed foods with accurate use-by dates, helping to ensure food safety and quality.